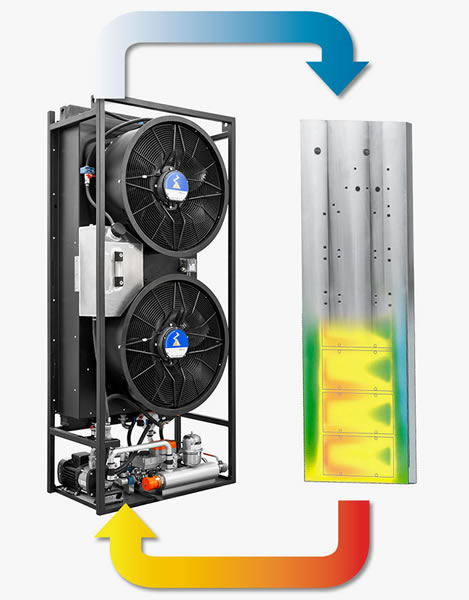

We have two specialized R&D departments for liquid coldplates and cooling units, focused on the development and testing of all the new projects. Our capabilities includes selection and use of all possible needed accessories to provide the complete cooling chain like couplings, tubes/pipes and manifolds.

Our specific know how in liquid cooling enables our people to focus on demanding applications, where the reliability and performances are the key factors.

The two departments can also cooperate together providing an all-around approach to the thermal problem.