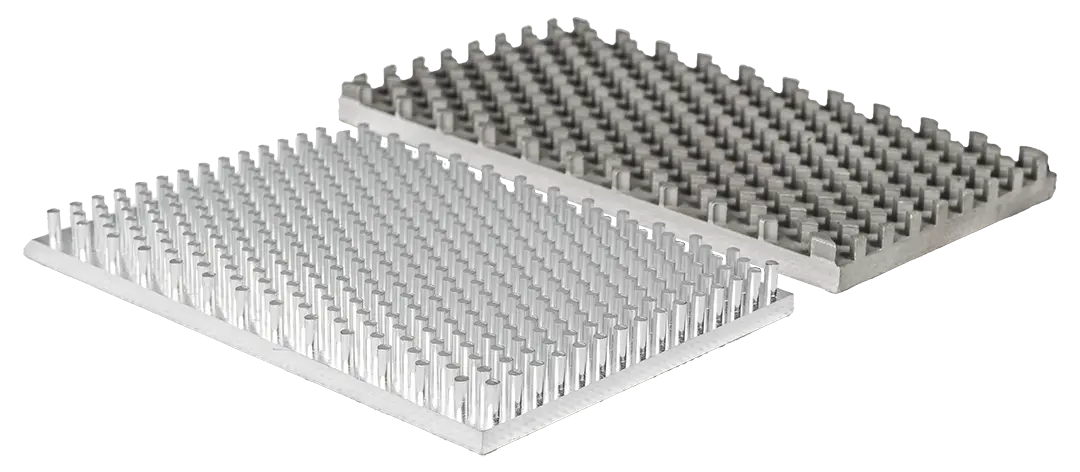

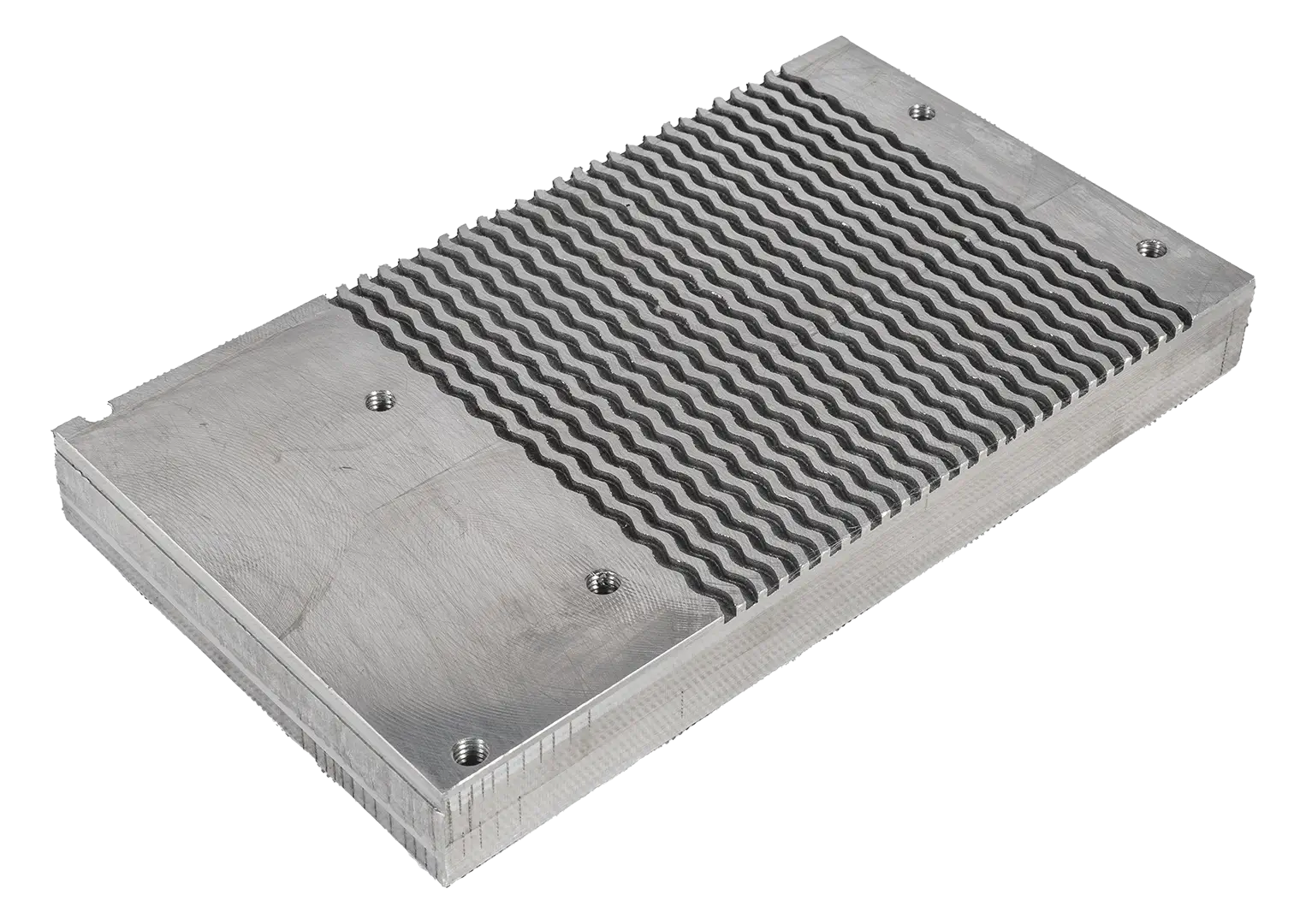

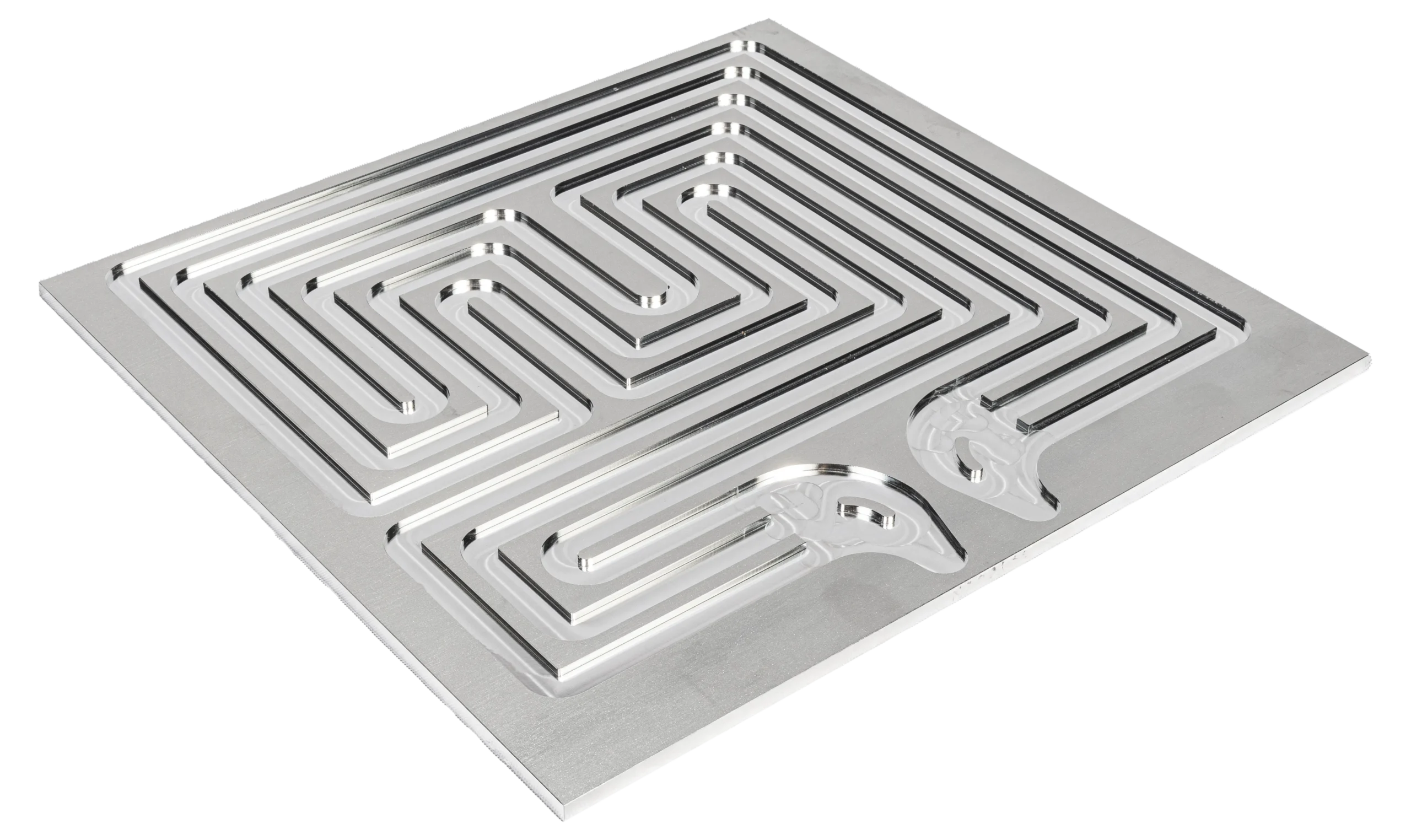

The Liquid Cold Plate B.U. offers aluminium liquid cold plates, from small size parts for LED or laser cooling, up to large unit for IGBT cooling. Thanks to our internal design team, we are able to design high performance cold plates optimizing them with CFD analysis and to perform qualification tests in our laboratory.

The cold plates are manufactured in our CNC department and joined together using vacuum brazing and FSW processes. Thanks to our in-house vacuum furnaces and FSW capabilities, we are able to provide prototypes in short time.

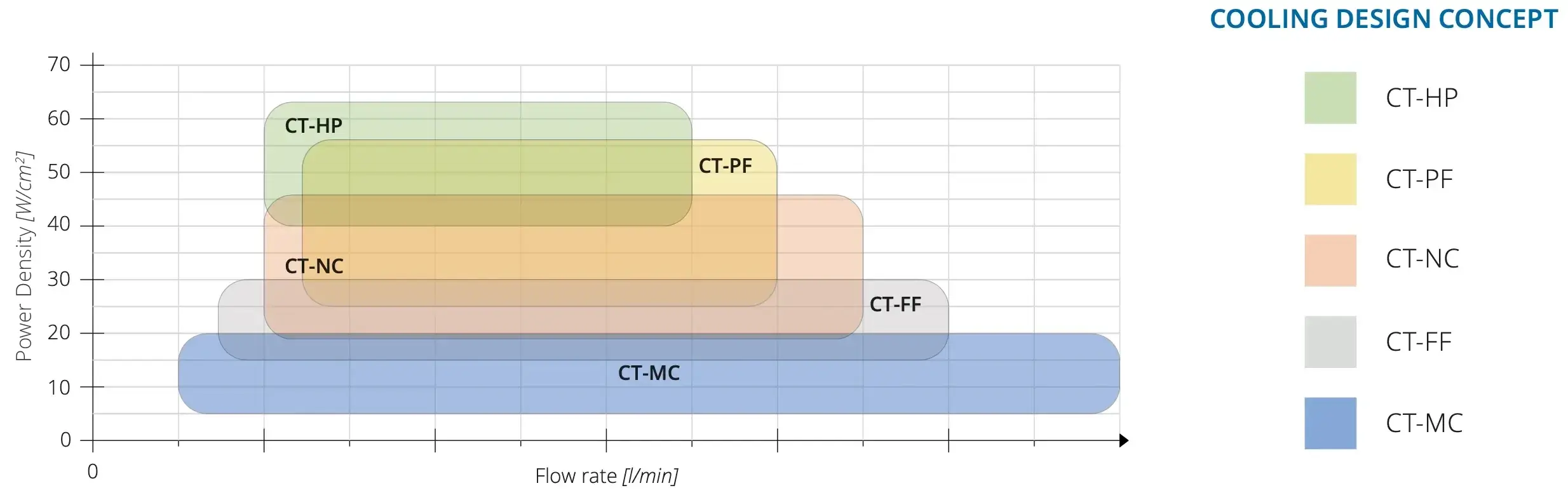

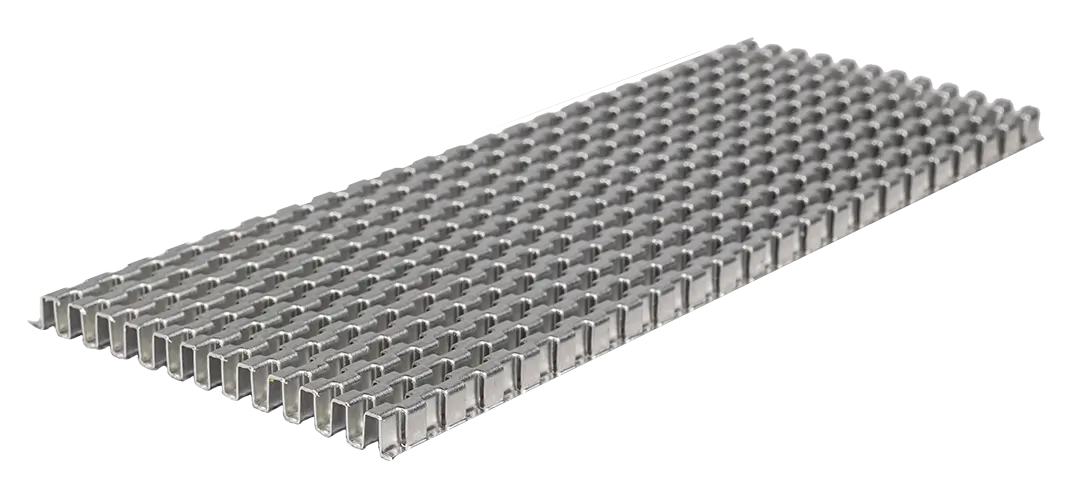

We can offer different type of cold plates, according to the thermal performances which are required.