RB series

Best thermal performance for applications with Rth: 5 – 8 °C/kW.

Aluminum can be joined with Friction Stir Welding or Vacuum brazing. Designed to meet the ighest thermal requirements with density > 20 W/cm2.

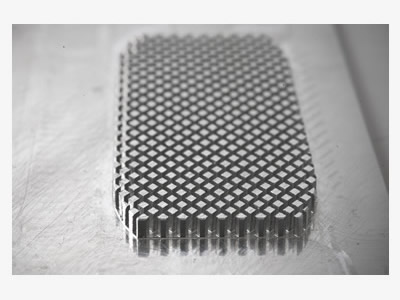

Complex geometry of each PIN creates turbulence with low flow rate values, resulting in a very high thermal performances vs. pressure drop.

Suitable for high end applications, like power converters for wind mills, traction converters and many more.

RB cold plates can be assembled using Friction Stir Welding using EN-AW6000-series aluminum alloy and die casting alloys or Vacuum Brazing using EN-AW6000-series and EN-AW3003 as core material and EN-AW4004 or ENAW4104 as cladding material.